Swagelok Netherland

Managing Supply Pressure Effect in Regulators

How to Manage Supply Pressure Effect (SPE) in Pressure-Reducing Regulators Used in Industrial Gas Systems Fluid system operators running a process line from a gas cylinder source may occasionally observe the phenomenon of outlet pressure increasing in a pressure-reducing regulator for no apparent reason. As the cylinder empties, the inlet pressure to the regulator decreases. Many skilled technicia …

Back-Pressure Regulators: How They Work & Tips for Analyzer Engineers

Back-Pressure Regulator Set-Up: Tips for Sampling System Engineers Back-pressure regulators play an important role in maintaining upstream pressure and protecting sensitive equipment in sampling systems used in many industrial facilities. To make proper use of a back-pressure regulator, however, sampling system engineers must be wary of a few common sampling system design mistakes. These include:

What is a Pressure Regulator & How to Choose

How to Choose a Regulator to Meet Your Fluid System Needs Pressure regulators play a crucial role in many industrial fluid and instrumentation systems, helping to maintain or control desired pressure and flow in response to system changes. It is important to select the right regulator to keep the system operating safely and as intended—the wrong choice can lead to inefficiency, poor performance, f …

Sample Cylinder Maintenance FAQ: What You Should Know

FAQ: What You Should Know About Sample Cylinder Maintenance In any industrial environment where grab sampling is a part of regular operations, keeping your sample cylinders in safe working condition is a necessity. Damaged or malfunctioning cylinders can present a safety issue for staff, and may compromise the accuracy and integrity of your sampling practices. All of this makes regular, proactive …

The 5 most common revelations experienced in process analyzer system training

A process analyzer sampling system is one of the most challenging systems within your plant. Not only is it challenging to design, it’s also challenging to operate accurately. If you make one minor adjustment here, you may end up having to make a major one elsewhere. It’s no wonder Swagelok gets so many good questions, and attentive trainees, during our process analyzer sampling system (PASS) trai …

5 Considerations For Hydrogen Fuel Cell Fittings

Five Qualities to Look for in Fittings for Hydrogen Fuel Cell Technology One of the most formidable challenges in the development of safe, reliable, and leak-tight hydrogen fuel cell vehicles and infrastructure is the nature of hydrogen itself. Hydrogen is a small-molecule gas. It can easily escape through the tiniest of crevices and diffuse into the materials designed to contain them. In the tran …

Top 5 Hydrogen Infrastructure Best Practices

The Top 5 Best Practices for Designing Hydrogen Fluid Systems Hydrogen is one of the world’s most promising sources of clean and sustainable energy and power. From transportation and material handling to stationary, portable, and emergency backup power, it’s useful in a range of applications—and industries everywhere are taking notice.

An Introduction to Grab Sampling

Grab sampling… …also known as spot sampling, laboratory sampling, field sampling, or sometimes just sampling—involves the collection of a sample fluid in a pipeline, tank, or system. The sample is then analyzed to help operators validate process conditions, evaluate products for environmental emissions according to local regulations, and detect whether the product is up to customer specifications.

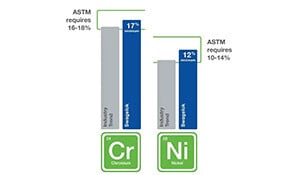

Selecting Materials for Corrosion Resistance

Materials Matter: Selecting the Right Material for Corrosion Resistance An offshore platform can have nearly 50,000 feet of tubing, more than 20,000 fluid system components, no fewer than 10,000 fittings, and as many as 8,000 mechanical connections. That’s why when selecting materials, it is important to choose corrosion resistant metals.

Pitting Corrosion vs. Crevice Corrosion

Pitting Corrosion vs. Crevice Corrosion: Identifying the Differences Corrosion—the deterioration of engineered materials by chemical interaction with their environment—is an extraordinarily costly problem. Unchecked stainless steel corrosion in tubing systems is a leading cause of profit loss for offshore and nearshore applications, costing upwards of $1 billion each year, according to research fr …