Custom Assemblies

If you’re short on manpower, Swagelok Netherlands can provide an extra set of hands by fabricating your fluid system assemblies for you.

In-House Design, Fabrication, Assembly, and Testing

Led by Technical Competence & services Director Eric Zwager, our team of certified fluid system advisors, designers, assemblers, and testers work in a state of the art shop in Waddinxveen. No project is too large or too small, and often we can help even if time is tight.

From your idea…. To your solution

1. Idea

2. Design

3. Solution

Safe, economical designs

Certified experts review your design or collaborate with you to make one. We ensure economical design and pull from inventory steps from our shop. Tight deadline? Often we can accelerate your project. Need a shelter, rack, header, etc? We make those too.

In-house testing

Choose from hydro, pneumatic, and helium leak testing. We test down to 1x10-6 — tighter tolerance than traditional leak testing. Our in-house capabilities allow for modifying valves and doing repairs.

Expert support

Our goal is seamless integration with your fluid systems, people, and processes. We come onsite to personally answer any questions from installers, operators, technicians, and managers. Practice operation, discuss maintenance, and fine-tune while our expert is on hand.

Benefits

Reliable Components

Flexible and scalable

Cost Savings

Inventory

Quick Turn

Testing Options

Installation Support

Onsite Evaluations

Swagelok Warranty

Frequently Asked Questions

Design

Some assemblies may incorporate non-Swagelok components. Each project is evaluated individually.

A fluid systems expert on our dedicated Custom Solutions team. Should a project warrant it, we can draw on 100 more Swagelok Engineers around the world. All are technical experts in fluid and sampling systems and have comprehensive knowledge of Swagelok products and their applications—including tubing, fittings, valves, and more.

Yes. We make sure we fully understand your needs, including time pressure. With our huge warehouse onsite, there's rarely any waiting for components to arrive.

Fabrication

We can fabricate just about anything that has fluid system components on it.

We offer benchtop, and hand tube bending with various materials. Our CNC bender can bend stainless steel tubing of 1/4" to 1", with any wall thickness, to any angle, up to 42" radius.

Yes. For example, we build bottle racks. Our shop has all the equipment for each step required to deliver a total solution—like cutting, welding, and bending.

Assembly

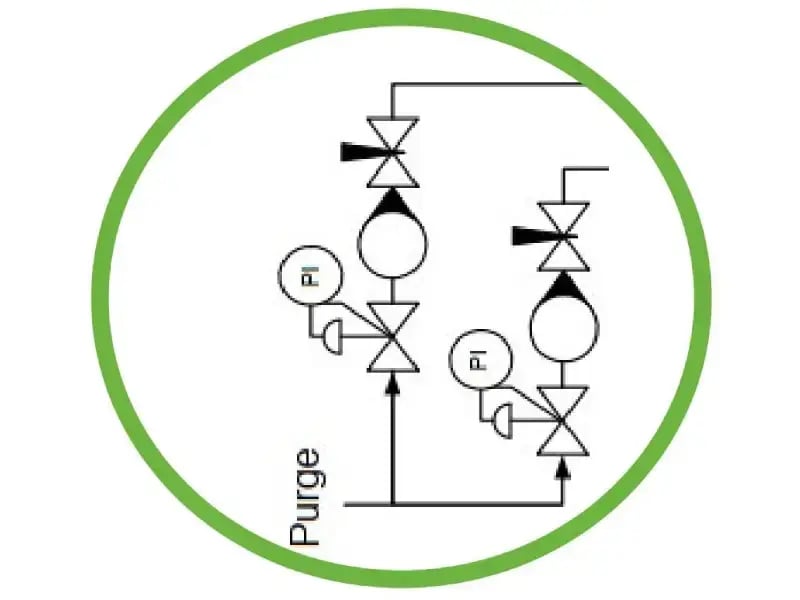

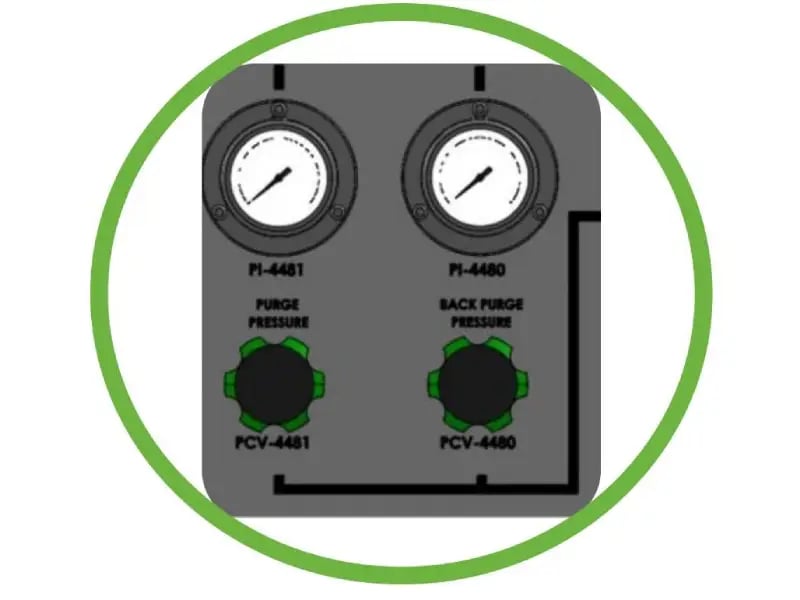

We build analytical subsystems, gas distribution systems, grab sampling systems, hose assemblies, regulator assemblies, and more. Capabilities include but are not limited to the following: Connecting tube fittings with valves, filters, hoses, etc. Assemblies with hose insulation, protection, assembly. Assemblies with threaded, VCR, VCO, welded, other seals. Assemblies with tapered and parallel pipe threads. Assemblies using Modular Platform Components (MPC). Assemblies that incorporate wiring, automation, transmitters, relays, pumps, and other non-Swagelok components.

Some assemblies may incorporate non-Swagelok components. Each project is evaluated individually.

Swagelok-certified technicians who have undergone extensive training to ensure consistent precision fabrication and assembly.

Testing

Leak testing is included. In addition to standard testing, we can do helium leak testing and hydrostatic testing.

Available are CAD drawings, piping and instrumentation diagrams, Bill of Materials, and warranty information. Our Product Test Reports provide exhaustive performance data, third party certifications, and approvals.

We can leak test and provide hydrostatic testing, pneumatic testing, and helium leak testing.

Documentation

We have Swagelok Quality Systems (SQS), which defines processes and procedures. And are also ISO 9001:2015 certified.

Yes. You receive CAD drawings, Bill of Materials, and warranty information.

We are glad to address that with you. Our team members have deep experience in fluid systems applications for conventional oil and gas, steam-assisted gravity drainage (SAGD), chemical and petrochemical refining, alternative fuels, power generation, and research and development industries. They know the regulatory standards that apply here and know about the trends that may be affecting your business.

Yes. Your assembly is covered by the same Swagelok warranty as our individual parts.

About Swagelok Netherlands

Industrial fluid system components, assemblies, and professional services.

- Components: Swagelok makes 6,200 standard parts, grouped into about one dozen product lines. You can find tube fittings, valves, hoses, regulators, tubing, and much more.

- Assemblies: we build custom analytical instrumentation solutions, gas distribution systems, grab sampling systems, hose assemblies, regulator assemblies, and a range of other solutions.

- Advice: we have Swagelok-certified field advisors who can help diagnose fluid system issues, review fluid system plans, and advise on how to improve fluid system efficiency, cost effectiveness, and safety.

- Training: we offer a range of Swagelok training seminars to build your team's skills

Often yes. Our Field Advisory resources are here to work with your team via phone and video technologies to share ideas, collaborate, trouble-shoot, and diagnose together. We can work with you on whatever fluid system challenges you and your business are facing. Not only do we have Swagelok certified Field Service Technicians on-call, but we also can tap into our network of 50 Swagelok Field Service Technicians in the world when we need additional resources.

Contact your dedicated accountmanager

- If your organization operates in the Netherlands, please choose an option at the top of this page to contact us.

- If you are not in the Netherlands, a Centre closer to you may provide the best service. To find one of the 200+ other Swagelok Sales and Service Centres worldwide, please visit this page →

Fluid System Advice — Onsite or Remote

Not sure what is/isn't needed? Our Field Advisors are here to help. Both onsite and remote support are available.

Requesting evaluation and advice from a Swagelok Netherlands Field Advisor is a great way to start any project involving fluid systems. We listen to understand your priorities, gather information on your systems and routines, conduct onsite inspections as appropriate, and offer detailed recommendations. Our goal is to help identify opportunities to increase reliability while lowering your operating costs and minimizing risks.