Swagelok grab sampling systems

Selection and accessories

Selecting a Swagelok grab sampling system

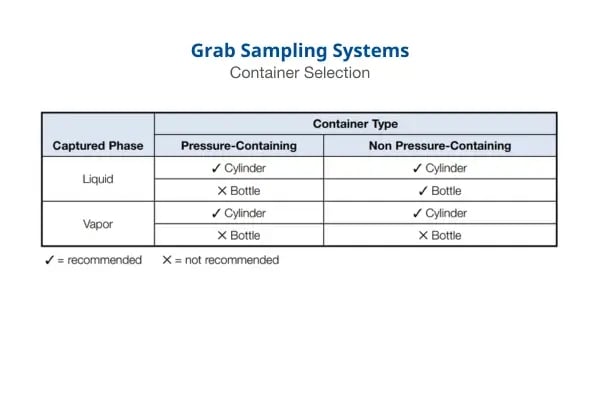

Two system types allow for capture into one of two types of containers: pressure‑containing metal cylinders as found in the Grab Sample Module (GSM) or non-pressure‑containing glass or polyethylene bottles as found in the Liquid Only Sampling Module (GSL).

Container type

Sample cylinder – the GSM system is for samples with a vapor pressure above 14.7 PSIa (1.01 Bara) at ambient conditions. The GSM uses pressure-rated sample cylinders which prevent the sample from escaping, even under pressure, and are durable to prevent accidental breakage. The GSM is the most reliable method of capturing a sample.

Bottle sampling – the GSL system is for samples with a maximum vapor pressure of 14.7 PSIa (1.01 Bara) at ambient conditions. The design allows for the use of less expensive glass laboratory bottles to draw and store the sample. Using bottles also provides immediate feedback on the visual quality of the sample stream.

Collaboration

Ensuring your grab sampling system is suitable for your particular purpose is key. Temperature, pressure, phase, container type, materials of construction, and where the panel will be installed are just a few of the criteria to consider in order to properly specify a grab sampling system.

Our team takes you through a checklist of details to ensure the panel we recommend will meet your system needs. The product selection matrix (below on this page) provides some common system criteria that may help you with the decision making process. Next, a certified expert will review your information and recommend a panel per your requirements.

Specification

Using our standard panel designs as a platform, we can work with your team to substitute comparable Swagelok and non-Swagelok products if necessary; add products within the existing schematics, sample coolers, flow meters, shut-off valves, drain valves, etc; and make changes in the layout.

If needed we can make structural changes/additions panel/bracket materials, enclosures, etc.; convert to larger/smaller tube size (or metric); and recommend alternate materials of construction. Likewise, we can make flow/pressure drop calculations (and make changes based on results) and/or recommend sizing of sample coolers/heaters and enclosure heaters (using vendors’ applications engineering).

Swagelok grab sampling advantages

Simultaneous control of fluid routing

A key feature of the GSM is the switching valve that directs flow. Using the Swagelok 40G series ball valve for this switching valve, configurations are available with either 2 or 3 valves.

Simultaneous control of fluid routing means fewer steps required to draw a sample. The likelihood of errant sampling is reduced and a clear indication of sequencing is provided to the operator. This valve assembly is a standard on all GSM panels as well as fixed volume GSL panels.

Closed-loop system

The closed-loop sampling system pulls from a positive-pressure process and returns back to the process at a lower pressure location (e.g., upstream of a pump), using the differential pressure to drive the fluid through the sample system. This circuit draws a flow path that connects to the sampler then returns to the process or to flare.

With some arrangements a GSM can be left in the bypass or sample position indefinitely, keeping the transport lines fresh (with zero flushing time) and ready for sample capture. A rupture disc is an available option for every GSM system. A relief valve can also be added to the sampling systems.

Liquid sampling using glass

The GSL design allows for the use of less expensive glass laboratory bottles to draw and store the sample. Using bottles also provides immediate feedback on the visual quality of the sample stream. Swagelok GSL systems use the same switching valve as a GSM system to provide simplified operation for complex tasks. The GSL systems also include Sentry Equipment’s Model MVS to draw a sample into a bottle.

Grab sample cylinders

A sample cylinder is required for every GSM system and should be ordered separately when purchasing a new GSM. Various configurations of sample cylinder assemblies, defined as Grab Sample Cylinders (GSC), are available.

- Five standard cylinder sizes (150, 300, 400, 500, & 1000 cm3)

- Multiple cylinder and valve material options

- With or without purge bypass tube

- Choice of quick connects

- Accessories: Outage tubes, needle valves, rupture discs, and carrying handles (view Accessories)

- Cylinder treatment/certification

- Stem and body protectors

- PTFE coated inner wall, SilcoNert® coating, or electropolished inner diameter

- DOT or TPED approved

GSC assembly descriptions

Standard version

For general use or for use with GSM systems without a purge option.

Purge version

For use with GSM systems with a purge option specified.

Note: Regardless of orientation and implementation, the flow direction on all GSC isolation valves is away from the cylinder. Needle valves have a preferential shutoff direction for restraining pressure and the valve will be oriented such that it is best situated for resisting the internal pressure of the cylinder.

Sample cylinder accessories

Several options are available for your grab sampling system, such as additional instrumentation - gauges, flowmeters, and transducers; sample coolers—sentry sample coolers; process connections—threaded and flanged connections; enclosures and stands; automation—add a pneumatically or electrically actuated valve to automate your sampling sequence; and exotic alloys—certain components are available in alloy 400, alloy C-276, or alloy 600.

Outage tubes

- Made from 316 stainless steel or alloy 400 tubing

- Offered in 1/4 or 1/2 in NPT sizes

- Marked "Outage Tube" for identification

Outage tubes provide a vapor space of the desired volume in cylinders containing liquefied gases, so that liquid in the cylinder can expand if the temperature increases. Without enough vapor space, a small temperature increase can cause the liquid to expand and increase the pressure dramatically. Outage tubes are welded to the male inlet end of an adapter or tee. This adapter or tee is then threaded into the female port of a sample cylinder. The tubes can also be welded directly to the male inlet of a Swagelok non-rotating stem needle valve. The valve is then threaded into the female port of a sample cylinder.

Nonrotating-stem needle valves

- Compact, rugged design is available in straight and angle flow patterns

- Protective handle prevents contaminants from entering functional valve parts

- Orifice sizes from 0.093 to 0.218 in. (2.4 to 5.6 mm) are available.

- Flow coefficients (Cv) from 0.12 to 0.53 are available

- Female NPT, male NPT, Swagelok tube fitting, and mixed end connections are available

- Pressures up to 3000 psig (206 bar)

- Temperatures up to 450°F (232°C) with PEEK stem tip

- Stainless steel, brass and alloy 400 materials

Needle valves have a preferential shutoff direction for restraining pressure and the valve will be oriented such that it is best situated for resisting the internal pressure of the cylinder. The D Series is widely used due to its replaceable stem tip and compact handle.

Rupture disc units

Swagelok rupture disc units protect sample cylinders from over pressurization by venting the cylinder contents to atmosphere. The use of a rupture disc is recommended with chemicals that may rapidly expand and pressurize due to temperature changes.

The rupture disc is welded to a body that is threaded into a valve body or a rupture disc tee and sealed by an elastomer O-ring. The rupture disc can be easily replaced without removing the valve or the tee from the cylinder.

Carrying handles

The carrying handle is an optional purchase that provides a convenient and safe way to carry sample cylinders. The handle is constructed of 304 stainless steel and is available for use on 300 cm3 and larger cylinders.