Swagelok Knowledge Center

Top 5 Aha Moments from Process Analyzer System Training

A process analyzer sampling system is one of the most challenging systems within your plant. Not only is it challenging to design, it’s also challenging to operate accurately. If you make one minor adjustment here, you may end up having to make a major one elsewhere. It’s no wonder Swagelok gets so many good questions, and attentive trainees, during our process analyzer sampling system (PASS) trai …

Key Considerations for Hydrogen Fuel Cell Fittings in Clean Energy

Five Qualities to Look for in Fittings for Hydrogen Fuel Cell Technology One of the most formidable challenges in the development of safe, reliable, and leak-tight hydrogen fuel cell vehicles and infrastructure is the nature of hydrogen itself. Hydrogen is a small-molecule gas. It can easily escape through the tiniest of crevices and diffuse into the materials designed to contain them. In the tran …

Top 5 Hydrogen Infrastructure Best Practices

The Top 5 Best Practices for Designing Hydrogen Fluid Systems Hydrogen is one of the world’s most promising sources of clean and sustainable energy and power. From transportation and material handling to stationary, portable, and emergency backup power, it’s useful in a range of applications—and industries everywhere are taking notice.

Essential Guide to Best Practices in Industrial Grab Sampling

Grab sampling… …also known as spot sampling, laboratory sampling, field sampling, or sometimes just sampling—involves the collection of a sample fluid in a pipeline, tank, or system. The sample is then analyzed to help operators validate process conditions, evaluate products for environmental emissions according to local regulations, and detect whether the product is up to customer specifications.

Selecting Materials for Corrosion Resistance

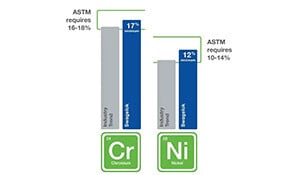

Materials Matter: Selecting the Right Material for Corrosion Resistance An offshore platform can have nearly 50,000 feet of tubing, more than 20,000 fluid system components, no fewer than 10,000 fittings, and as many as 8,000 mechanical connections. That’s why when selecting materials, it is important to choose corrosion resistant metals.

Pitting Corrosion vs. Crevice Corrosion

Pitting Corrosion vs. Crevice Corrosion: Identifying the Differences Corrosion—the deterioration of engineered materials by chemical interaction with their environment—is an extraordinarily costly problem. Unchecked stainless steel corrosion in tubing systems is a leading cause of profit loss for offshore and nearshore applications, costing upwards of $1 billion each year, according to research fr …

Mastering Tube Fitting Installation for Safe and Efficient Operations

Tube Fitting Installation: Everything You Need to Know Reliable industrial fluid systems are essential for safety, efficiency, and profitability in your plant—and their ability to operate dependably relies on many factors. Some of the most important include proper tube and tube fitting installation as the system is initially assembled and maintained throughout its useful life.

Detecting and Preventing Costly Fluid System Leaks in Plants

Common Causes and Costs of Fluid System Leaks Fluid system leaks are a common occurrence in most plants. Because you’re charged with maintaining your plant’s safety and profitability, even the smallest leak can present an issue. That’s why it’s helpful to understand how and why leaks occur, how to locate and test for them, and ultimately how to develop a strategy to address and reduce leaks plantw …

Streamline Operations with Swagelok Quick Connects

Unveiling the Benefits of Swagelok Quick Connects In the dynamic world of engineering and industrial applications, efficiency and safety are paramount. Swagelok Quick Connects are engineered to meet these demands, offering a seamless way to enhance operational efficiency by minimizing spillage and air inclusion. These connectors are designed for a variety of applications, ensuring that processes r …

Enhance Hose Safety & Reduce Plant Costs with These 3 Essential Steps

Industrial hoses often do not get the attention they deserve. Most manufacturing facilities have specifications and policies concerning tubing, fittings, and valves on pressure-containing systems, but hose safety continues to be left out.